Our mission

Development of packaging solutions

- Focusing our work on a policy involving the reduction in weight, eco-design, recycling, and reuse of packaging.

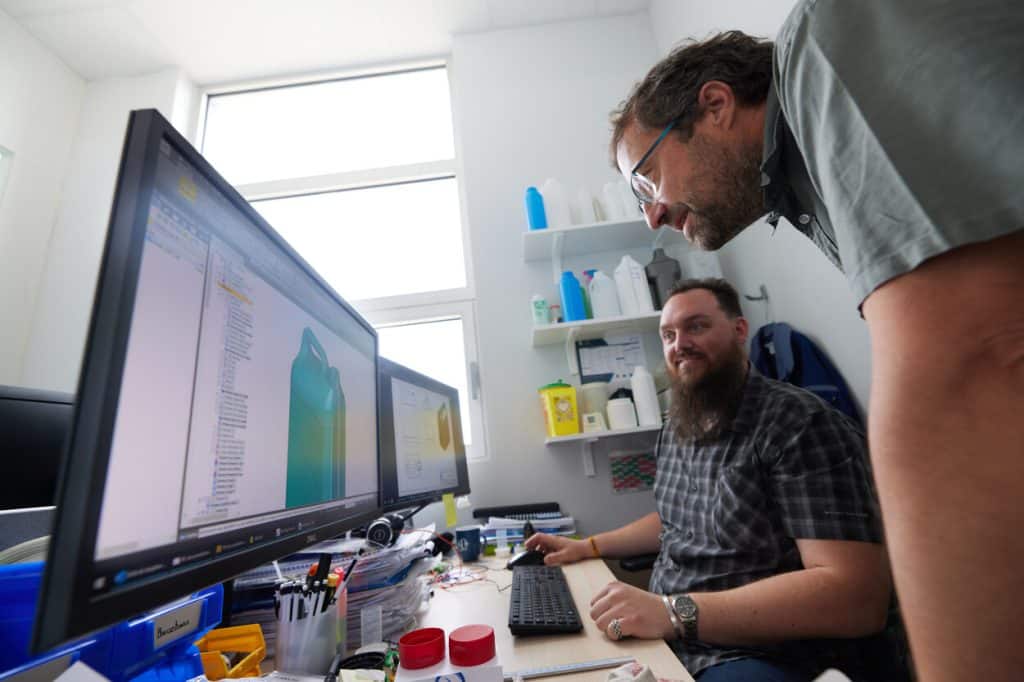

Groupe Roullier began its plastic processing activities in 1988. Its aim was to provide plastic packaging solutions that matched market demand. From design to industrialisation, the Group packaging division, managed by Agriplas-Sotralentz Packaging, provides its customers with a differentiation strategy, particularly through the creation of custom-made products.

Expertise

Processing of plastic materials

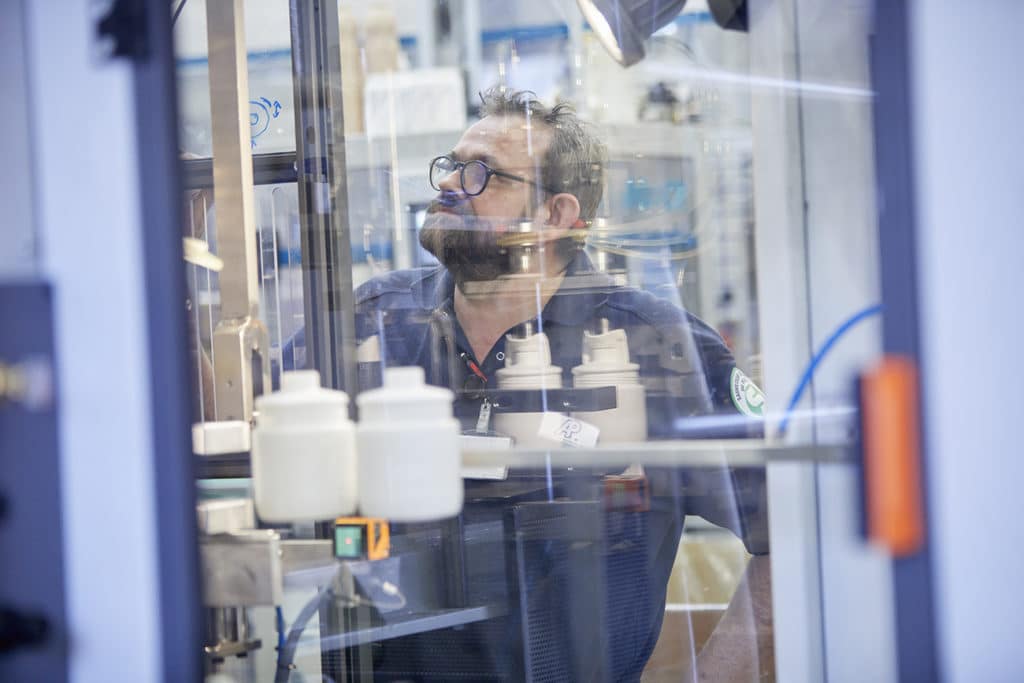

Our two manufacturing processes, blow-moulding and injection-moulding, allow us to produce a wide variety of standard or specific products in different colours. Our design offices expand our range every year by developing several new standard or custom-made products. The packaging is UN-certified, complies with UN recommendations, and fulfils the ADR/RID/IMDG regulations in force. This activity consists of 3 industrial units, 37 blow-moulding machines, 7 injection machines, and an internal laboratory to carry out UN certification tests.

Our range

Covering more than a dozen industrial customer markets, Agriplas-Sotralentz Packaging has the most complete range on the market in France (more than 1,000 products). It designs and manufactures plastic packaging with capacities ranging from 15ml to 1,000L (flasks, jars, jerrycans, caps, IBCs, plastic accessories and technical items). For use in the chemical, food, detergent, health, and lubricants industries, the packaging developed by Agriplas-Sotralentz Packaging meets the various challenges faced by each of these fields.

Nicolas Desvages

General Manager

“In a context where standards are rapidly evolving and the transition towards more responsible materials is accelerating, our expertise in plastics engineering serves as a true benchmark. We design reliable and high-performance solutions, crafted to meet the technical requirements of our clients while aligning with a sustainable trajectory. Beyond industrial mastery, we play the role of a facilitator: we help our partners anticipate changes, optimize their choices, and gradually integrate the principles of the circular economy. It is this approach, combining innovation, responsibility, and proximity, that guides our commitment and structures our contribution to stakeholders in the industry.“